Measurement technology for efficient systems

The right measurement technology in industrial companies ensures maximum energy efficiency and a secure energy supply. It records energy flows, detects faults, and helps the company to avoid bottlenecks.

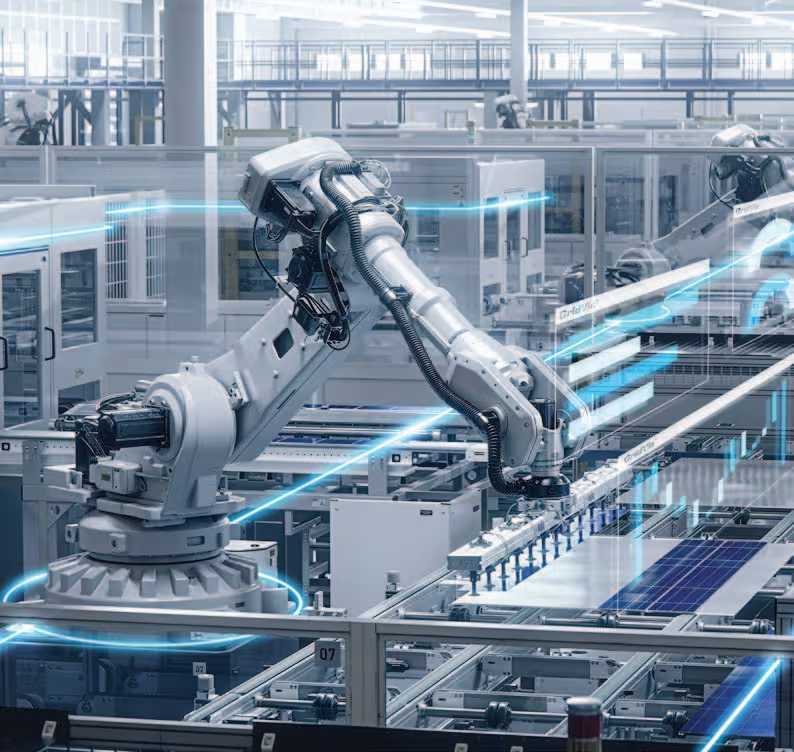

Holistic solutions for the manufacturing industry

Successful companies are able to increase their energy efficiency and at the same time decrease costs. The use of comprehensive measurement technology plays an important part here. It supports companies to monitor and control their own energy consumption. This guarantees a secure and reliable energy supply.

Reducing energy consumption helps to decrease operational costs long term. This in turns helps the company to reduce its environmental footprint.

Challenges in the energy supply sector

Companies face the challenge of increasing energy efficiency whilst reducing CO2 emissions to lower costs and achieve environmental objectives. A comprehensive energy management system and intelligent load management helps save resources and ensure a sustainable supply. This does not just cover more stringent statutory requirements, but also lays the foundation for a sustainable future.

Increase energy efficiency and decrease CO2 emissions.

High energy efficiency makes a significant contribution to reducing operational costs, minimizes environmental impact and helps to comply with ever stricter legal regulations, such as the Energy Efficiency Act.

By implementing a modern energy management system, companies can monitor and analyze their energy consumption in detail in order to identify and improve inefficient processes. The early detection of deviations in energy consumption enables improved performance analysis of the machines for reliable energy efficiency reports and the monitoring of specific energy indicators for efficiency optimization. The data can be seamlessly incorporated into an energy management system in accordance with standards such as ISO 50001 or environmental management.

Janitza offers measurement technology for the data acquisition of electrical energy and the corresponding software to process and analyze data from energy sources such as electricity, gas and compressed air as well as other process media such as water, nitrogen, etc. in accordance with standards. Further information can be found in Energy management. By recording all energy sources and auxiliary materials, CO2 emissions from energy can be visualized and used as the basis for achieving sustainability targets. As suppliers, smaller companies are also affected by such requirements Further information can be found in “On the path towards a CO2 balance.”

Avoiding load peaks and reducing costs

High-performing load management allows energy flows to be controlled intelligently. This means that companies can reduce their load peaks and as a result also their energy costs, save resources, and guarantee the stability of their own mains supply.

The ability to control the electrical loads prevents overloading and ensures an even distribution. Predictive peak load reduction achieved through targeted consumer control can significantly reduce grid connection costs. Energy distribution systems can be utilized more efficiently as fewer reserves are required, which also saves costs.

In addition, the use of renewable energies is optimally supported by load management, for example in distributing and controlling self-generated energy for charging electric vehicles or the use of an energy storage system. The aim is for the company to consume a large proportion of the energy generated in its own grid. This reduces energy costs for the network operator and makes the use of renewable energy such as photovoltaics more efficient and more profitable.

Further information can be found in:

Guaranteeing security of supply

Security of supply is essential in many industrial areas, as even momentary interruptions or faults in the power supply can result in high costs and damage to systems.

The power quality must be monitored in compliance with standards to ensure a secure supply. The continuous monitoring of power quality and analysis of compensation currents also enables companies to assess the state of machines and systems. Unscheduled maintenance or production downtimes are avoided thanks to the early detection of leakage currents or load changes. Detailed records are used to analyze the power quality, schedule maintenance and ensure compliance with relevant standards such as DIN EN 61000-2-4 as well as to document and analyze negative changes and improvements in the energy supply.

Increasing fire protection and installation protection

The functionality of production facilities can be monitored and logged using a comprehensive residual current monitoring system.

Fires and failures can be detected and prevented before they occur, therefore ensuring operational security. Effective troubleshooting leads to shorter downtimes and improved availability of the power supply. This helps to minimize unscheduled stoppages and production downtimes. Manual isolation testing in accordance with DGUV V3 can be avoided thanks to constant monitoring if certain requirements are met; the remaining part of the test in accordance with DGUV V3 can be carried out without a break in production while the systems are in operation. Costs are reduced and production downtimes are avoided without risking the safety of machines and systems.

Janitza measurement devices for industrial companies

Janitza offers specific products for every application to guarantee the best power and safety of your energy supply.

Flexible and scalable system integration

- Simple integration in new or existing energy management systems (EMS)

- Modularly expandable devices

- Direct integration of other sensors into the communication chain

- Simple integration into switchboard cabinets and distribution cabinets

- Simple expansion of the system to accommodate additional measurement points

- Web server integration directly on the measurement device

Reliable and accurate measurement technology

- Monitoring power quality, residual current (RCM) and energy consumption in a single device

- High accuracy class

- Residual current monitoring with savings potential for DGUV V3

- Certified measurements (MID and MID+) for bills and differentiation of third parties

Efficiency and future viability in operation

- Programmable intelligent devices

- Open and common communication interfaces in the industrial area

- Low power options for current transformers for minimized installation costs

- Long-lasting design

- Simple space-saving retrofit solutions

Suitable products

Janitza software for industrial companies

The power grid monitoring software GridVis® gives the user full control

Flexible and scalable system integration

- Customizable design of dashboards

- Free templates for dashboards and templates for diverse applications

- Tutorials for integration and e-learning

- Can be used at multiple sites without additional licenses (group license)

Analysis and reporting

- Analysis of CO2 emissions

- User defined report editor for your energy management

- Specially integrated reports for residual current monitoring, network utilization and high availability of systems

- KPI Manager and Alarm Manager

- Power quality analysis for a health check of the energy supply

- Certified to DIN EN 50001 with all the functions required by the standard and therefore eligible for subsidies via BAFA

Data integration and compatibility

- Integrated database JanDB or use of other databases, e.g. MSSQL

- All consumable media can be integrated into energy management (water, gas, heat, oil...)

- Measurement data recording via multiple communication channels

- Measuring devices from other manufacturers that are already installed can normally be integrated

Janitza services for industrial companies

Janitza's numerous practical-focused services provide you with the best possible support for the successful use of your energy measurement technology.

Comprehensive advice and support

- Service and support by Janitza and certified local partners, by telephone, web meeting or remotely

- Courses and training on-site and online

- Power quality analysis by certified experts

Project support and implementation

- Project collaboration for your planning

- Support from the initial consultation and measurement concept, through to assistance with installation, and commissioning and maintenance of the system

- Complete solution with a single point of contact for your energy management system

Technical implementation and maintenance

- Commissioning of the measurement technology and software

- Maintenance of the measurement technology and software

Further information

Get personal advice now

Your request is important to us and we guarantee fast and professional processing.